Digital technologies are becoming central to the core business strategies of MROs. Digital systems are no longer a peripheral tool but are changing how MRO is done. It can give companies a competitive edge.

At the recent 2022 MRO Americas trade fair, panels discussed the acceleration of digital uptake. This was in part necessitated by the pandemic; however digital technologies are now becoming more ingrained as business as usual. MRO providers are using digital options to optimise their operations and improve safety and quality, as well as drive down costs.

What are Digital Technologies?

Digital technologies in MRO can include a suite of applications, including: The Internet of Things (IoT) – a network of physical objects “things” that are embedded with sensors, software, and other technologies to connect and exchange data with other devices and systems over the internet; along with Augmented Reality (AR) – data collection, analysis and implantation through machine learning and artificial intelligence (AI); Additive Manufacturing (AM) – using Computer-Aided-Design (CAD) software or 3D object scanners to create 3D printed spare parts on-demand; Virtual Reality (VR), Robotics and Drones – for inspections and training.

How will Digital Technologies Help?

1. Connect all Segments in the Aviation System

The digital revolution of MRO will increase the efficiency of operations and reduce turnaround time. Digitalisation helps increase connections throughout the industry. It creates and manages data streams which can integrate all segments within the aviation system. This enables MRO providers to better collaborate with their customers and partners. It can also help to improve communication and collaboration between different teams within MROs. By connecting people, processes, and data, MRO providers can create a more efficient and effective MRO ecosystem.

2. Predictive Maintenance Advantages

Predictive maintenance is a major area where MROs can leverage digital capabilities for significant improvements. By using software that tracks performance data and analytics to identify patterns, predictive maintenance can help organisations schedule repairs and replacements before problems occur. This improves time management and minimises ground time, both saving costs.

By using analysing software MRO providers can also improve their maintenance schedules, parts ordering, and other processes such as automating workflows and integrating systems. Further improving efficiency while reducing costs.

MRO software provider Swiss-AS is preparing to roll out several new digital maintenance management products over the next couple of years.

3. Optimise Supply Chain and Resources

Digital MRO systems help ensure parts and equipment are sourced in good time, minimising turnaround time. The software also enables MROs to provide customers with more accurate costs. With current supply chain issues, both material and staffing (thought out the whole system), it can be very valuable software.

By optimising resource acquisition this can further improve sustainability, by being able to show where waste may occur and identifying positive changes to procurement. A recent survey found a key barrier to MRO growth was the increase in materials costs and the cost of sustainability measures. Digital technologies can help give drive down these costs and give MROs the advantage.

4. Increase Safety and Efficiency of Inspections

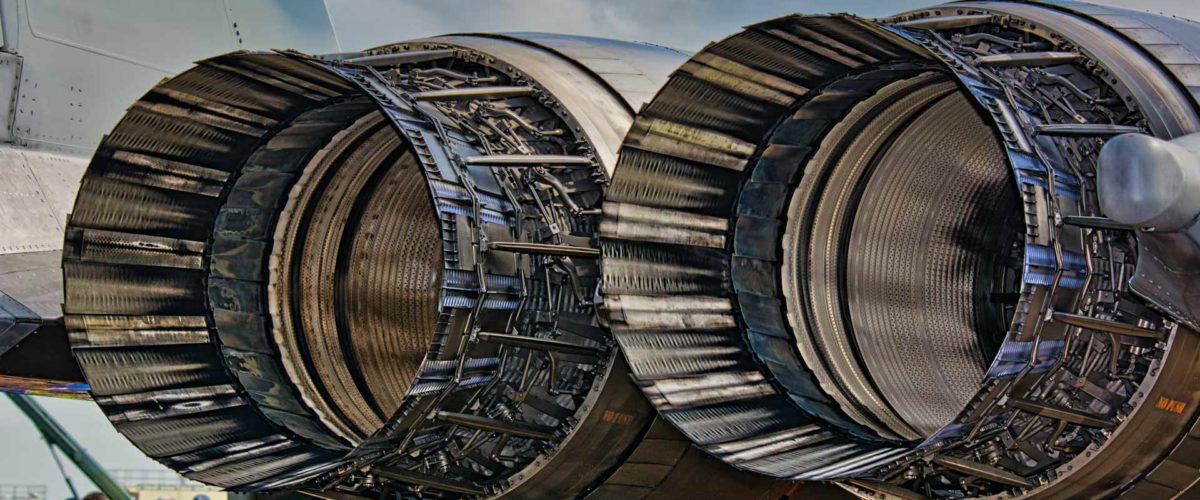

MRO providers are using drones and other robotic technologies to improve safety and efficiency. For example, drones can be used to inspect aircraft for damage, identify potential hazards, and track parts inventory.

While some visual inspections may now be done by sensor-equipped drones, many of the images will still need to be analysed by the human expert, along with the AI. The difference will be a clearer picture of hard or risky areas from the more relative comfort of a screen.

5. Simulations for Training Purposes

Digital technologies are also being used to create virtual reality (VR) and augmented reality (AR) simulations for training purposes. These simulations can help MRO technicians who are training or upskilling to work on complex equipment in an environment that is safe and able to be reset.

6. Selling or Buying Used Aircraft and Parts

MROs can benefit from digital software systems that make selling or buying parts (or used aircraft) easier, with a record of important information being more readily available, and verifiable.

Getting On Board

Getting on board is a team effort. It is important to consider, and include, all the players, at all levels. This should be done from the start (or from now!).

When you are at the training and implementation phase the users need to know not just how to use the new systems, but that it was designed by people who understood the job. One of the greatest barriers to the uptake of new technology in the workplace is users feeling that they weren’t asked, or that their job was not understood. The ‘why’ is another big question. Subject matter experts need to work with the digital technology developers, or those implementing the technology, so that the change is meaningful.

A Leading Aviation Digital Technology Partnership

An important joint venture in this expanding field is Digital Alliance. Initiated by Airbus and Delta TechOps in 2019 and now including GE Digital, this partnership brings together key areas of expertise to progress the development of digital aviation systems. Solutions are aimed across the industry and include GE’s predictive analytics to couple with Airbus’ Skywise suite of digital technologies and Delta’s operational and maintenance predictive models.

Conclusion

The digital revolution is still in its early stages, and there is much potential for further innovation and growth. Digital systems have moved from a useful tool to a necessary part of a successful business. As such, it is important to stay well-informed of the latest developments in digital MRO. MRO providers that embrace digital technologies will be well-positioned to keep a competitive advantage as aviation goes digital.